Tirimi RPS-03S Packing Workstation delivers high-speed, fully automated packaging with modular parallel robots, integrated vision systems, and precision grippers. Featuring rapid cycle times and quick changeovers, it ensures flexible, efficient handling for food, pharmaceutical, and varied industrial applications.

RPS-03S Packing workstation | |

Model | RPS-03S |

Robot model | BAT1300/1600-S6 |

Power supply | Three-phase AC380V±10%, 50/60hz |

Main material | Carbon steel spray/Stainless steel (optional) |

Size | 3745*2180*2600mm(for reference) |

Power | 6kw (It depends on the characteristics of the product) |

Air source | 0.6~0.8MPa |

Packing speed | Maximum 80 times/min |

Work environment | temperature:-10℃~+40℃, humidity:40%~80% |

Machine weight | ≤1500kg |

Applicable product individual weight | 1~3kg |

Applicable carton size | Maximum:650*420*300mm Minimum:400*250*200mm (Customization in size range) |

Applicable product category | Medium material |

The Tirimi Packaging Workstation Series adheres to a modular design concept, deeply integrating various standard packaging process steps for bagged, bottled, and other products. It fully leverages the high-speed and high-flexibility characteristics of parallel robots to achieve a fully automated packaging process, including visual inspection, gripper picking, material conveyance, carton conveyance, and equipment protection.

The system supports quick replacement of robots and grippers, allowing flexible adjustment of workstation layouts to enhance production flexibility. The parallel robot's base structure employs an XYZ three-axis linear motion combined with Z-axis rotation, achieving a standard cycle time of less than 0.4 seconds, meeting the high-speed material handling and assembly requirements of industries such as food and pharmaceuticals. The workstation features high integration: no independent control cabinet, built-in vision system, follow-up gripping, missed gripping alarm, precise positioning, and quick box change functions. Through a quick adjustment mechanism, the system can automatically adapt to various box sizes, enabling one-click switching and significantly reducing downtime during line changes.

The parallel robot consists of a high-rigidity aluminum alloy structure and a four-bar linkage motion mechanism, offering high-speed linear and rotational motion capabilities. A precision gripper is mounted at the end effector for rapid product pickup, maintaining high precision even at high speeds. The vision system assists in positioning, enabling real-time detection and guidance of materials. Through modular design, the robot can be deeply integrated with vision, grippers, conveyor lines, and support structures, achieving efficient and flexible packaging.

Left and Right Folding Support Mechanism: This mechanism uses a rotary cylinder to drive the support plate, simultaneously opening and maintaining support for the folding plates on both sides of the cardboard box (symmetrically arranged on both sides of the production line). After opening, the support plate is fixed in position. As the cardboard box continues to move forward, guide rods keep the left and right folding plates in a downward-pressed state, ensuring that the side folding plates do not bounce back. As described by Tirimi, the workstation is equipped with a “hinge support” module to precisely position the carton flaps.

Front and rear fold support mechanism: Similarly, the front and rear fold mechanism uses mechanical or pneumatic means to open the front and rear folding panels of the cardboard box and maintain their open state. It is equipped with position switches or sensors to monitor the degree of fold opening in real time, preventing interference with the parallel robot's grippers. The front and rear fold mechanism works in conjunction with the left and right fold mechanism to ensure that all four folding panels of the cardboard box are fully opened, providing stable support for the robot's packing process.

In applications such as food packaging, pharmaceutical bottle filling, and industrial parts packaging, the Tirimi packaging workstation offers significant improvements in efficiency and cost savings. The robot's high-speed, precise picking and placing operations greatly enhance production efficiency, enabling continuous automated operations at the workstation without being affected by fatigue; packaging speed and consistency far exceed those of manual operations. Automated packing eliminates the need for manual tasks such as box stacking and adjustment, which are now fully handled by robots, thereby reducing labor costs and minimizing human error. The workstation's quick-adjustment mechanism enables it to accommodate boxes of various specifications and sizes, facilitating production switching for multiple product varieties and small batches. In dynamic demand scenarios such as food factories, the system can swiftly transition from one packaging size to another with only minor adjustments to the fixtures, eliminating the need for prolonged downtime. Overall, this packing workstation achieves the production upgrade goal of “replacing human labor with machines” through its modular, highly automated design, significantly shortening production cycles, increasing output, and reducing labor intensity.

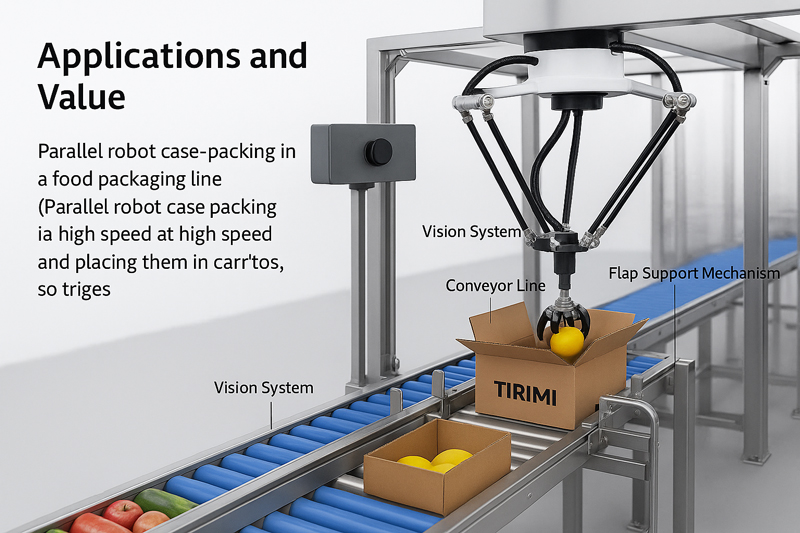

Parallel robot case-packing in a food packaging line. The robot picks fruits at high speed and places them into cartons. The system includes modules such as a vision system, automatic conveyor line, parallel robot body, and flap support mechanism. This automated case-packing process significantly improves production efficiency, reduces manual intervention during packaging, and demonstrates the value of the Tirimi workstation in typical food industry applications.

Key Features: Modular, scalable design to accommodate various products; high-speed, precise parallel robotic arm; fully automatic vision-guided operation with error correction; gripper-following grasping without manual sorting; left/right and front/back flap support mechanisms with collision prevention; quick carton change and multi-size adaptability; high integration and low maintenance costs. These advantages enable the Tirimi packing workstation to provide customers with stable, efficient, and flexible automated packing solutions.